Get the Tandy 102 (batteries out)!

Tags: computer tandy tandy-102 nec pc8300 kyocera batteries pickups

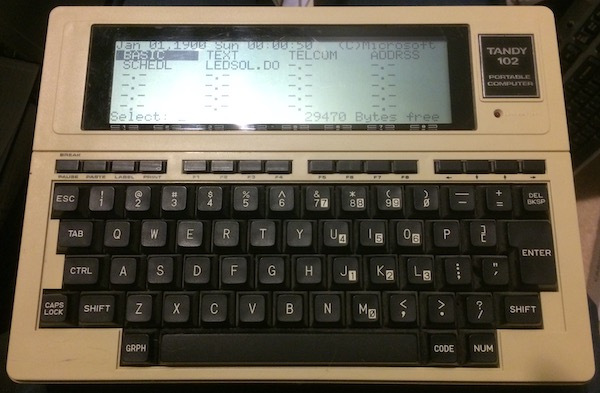

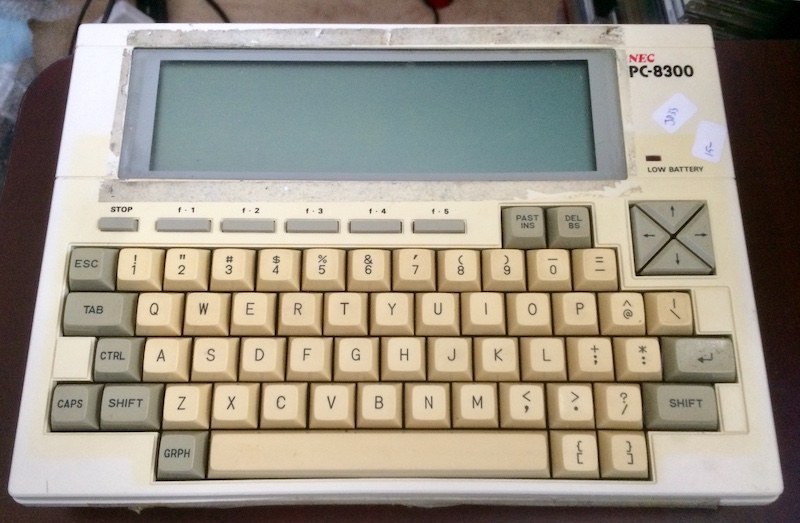

Sometime last summer, I spotted a local classifieds listing where someone was selling a “Tandy laptop.” After some interrogation, I determined that it was probably a Model 102. Another Kyocera sibling to join my NEC PC-8300?

I picked it up right away for $40, making sure to test it with fresh AA batteries. It came with a water-damaged BASIC manual, which I immediately filed away, and it seemed to work pretty well.

However, as with many other computers of the time period, the backup battery is an ever-present threat. I didn’t want to have to repair battery damage on both these machines, so I went ahead this weekend and clipped them out.

The Model 102

As the seller told me, it was his father’s Tandy 102. Apparently, the computer was once owned by national grain-mover Canadian Pacific Railway, and it was used to configure and debug some of the electronic signals they used.

This is another one of those cash transactions where the seller sped off as fast as humanly possible as soon as the money traded hands. Is there some kind of a theme developing here?

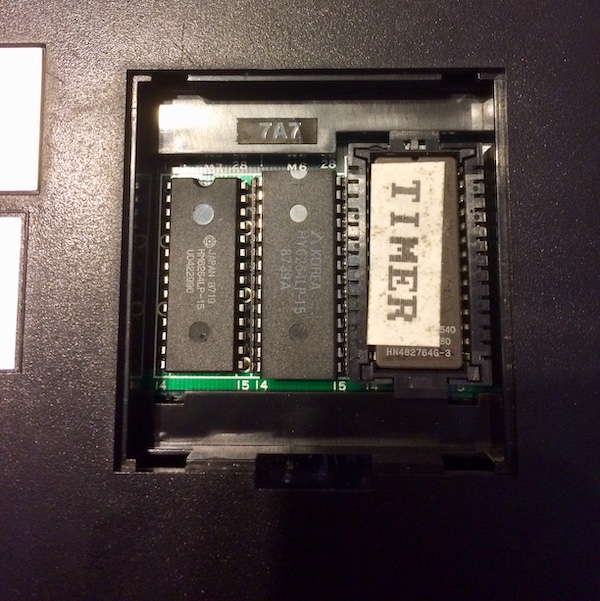

I didn’t notice anything special about this 102, not like the extensive modifications made to my Boeing PC-8300, so I chalked it all up to a neat story and went on with my life. In the course of dismantling the machine for the battery removal, I found this UV EPROM with a label over top of it, reading “Timer.”

This must have been some of the software they used. I had assumed the signals used a serial terminal through TELCOM, but apparently not.

My best guess is that I have to jump to some ROM-mapped offset in memory in order to run this software and/or install it on the main screen. I’m not sure what that address is yet, because I haven’t been able to locate a memory map for the 102. I’ll find it eventually and write it up in a future entry, assuming the software still works.

The label was peeling off (glue failure), exposing the UV window of the ROM. I printed off a new label on my labelmaker, very carefully de-staticked myself, and then placed it over the window. There! You’re safe from mild indirect sunlight causing ROM corruption over decades… trapped inside this machine where no sunlight can penetrate.

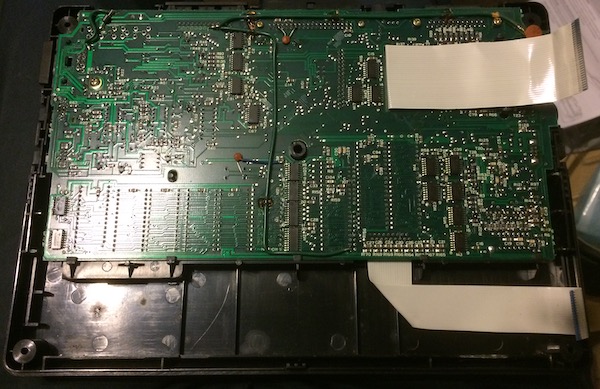

After I removed the four case screws, I had a lot of trouble popping the plastic clips holding this case together. They were really tight, especially considering the 1987 build date on the back. Maybe nobody has ever been inside this thing other than to install the Timer ROM through the hole in the back.

I didn’t know what to do with all the screws here, so I started removing them. Turns out you only need to remove the two outer screws, with washers, to remove the main board. Everything else holds in stuff like the ports and the battery box.

This is something I hadn’t noticed when I first tested the machine. The plastic battery box looks like it’s been pretty warped, and some of the contacts are bent. I’m not sure how I could fix this other than shimming it, or using a hot air gun to reform the plastics.

This caused me a lot of trouble later, but I didn’t realize it at the moment.

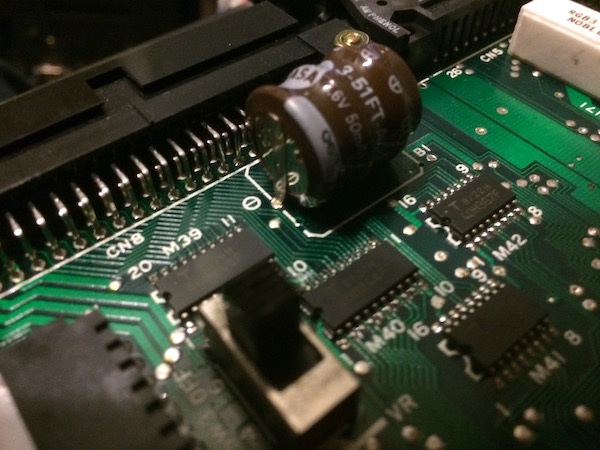

It wasn’t hard to find the battery on the top of the board. It’s sitting in the middle of everything! The negative terminal looks good - and that’s the end that usually leaks, right? - but let’s clip it out anyway.

That was a close one! I’ve never seen one leak from the positive terminal before, but it could have been really bad if I waited another few months or a year to do this job.

When I reassembled the machine and started it up, it didn’t go. I panicked and kept trying different combinations of the memory-battery disable switch and AA batteries. Eventually, I realized both that a near-dead set didn’t light up the “Low Battery” light, and that the battery housing was distorted.

After wiggling some of the batteries, the Low Battery light leapt to life. One of the battery-box contacts is bent and not making great contact. After cleaning all of them and then installing a new set of batteries and making sure all the springs were touching the negative terminals of the batteries, the Tandy 102 was alive again.

You’ll notice that, unlike the PC-8300, there is no “Y2K fix” done to this ROM. It’s most likely the factory one… for now.

Phew! That was a close one. Now I’ll try my luck with the even rarer and more delicate NEC PC-8300’s battery, too.

The PC-8300 assaults its battery

It’s fun seeing how NEC and Tandy specified this machine differently. On the NEC, fine-thread JIS screws are installed into little brass inserts like on the PC-6001. On the Tandy 102, ehhh - self-tappers into plastic are fine.

Surprisingly, the battery was in great condition here. It was another Yuasa MEMO POWER, like on the Tandy 102 and the PC-88s, and the battery hadn’t leaked a drop, nor did it look like it would any time soon.

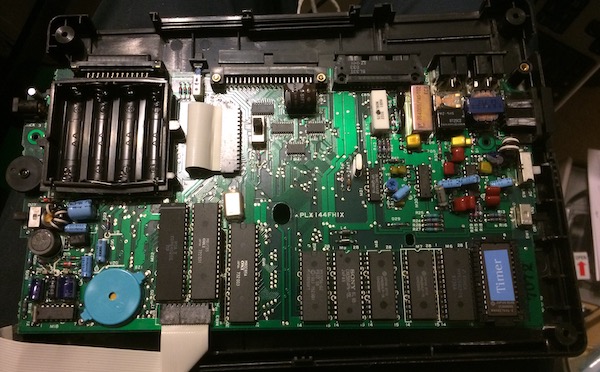

I clipped the battery out, but doing so was made annoying by this giant RF shield:

Although there is a lack of motherboard pictures of the 8300 on the Internet, I have to assume this was added not by NEC but by the previous owners - Boeing - when the machine was being put in use. Ground cables run everywhere from the shiny cardboard - to the back of the PCB onto several of the ports through their test-point pins. There’s a lot of foam that’s melted onto the back of the keyboard PCB as well, the shield is cut crooked, and the crimping job on the ground cables is pretty amateurish at best. It’s probably a field mod to reduce the risk of radio interference when debugging cockpit avionics or whatever it was this computer used to do for its paycheque.

There also seems to be a dollop of some kind of epoxy around the screws holding the lower PCB into the plastic, which makes me fearful for what I may encounter. I hope that I left enough metal in the clipped battery leads to potentially solder from the top, because I sure don’t want to try and heat gun this out if it really is stuck together.

After putting the machine back together to test, the OS was stuck, as it also was when I first bought it. After a few cycles of turning the backup memory power off and removing the battery and waiting for a few minutes, the RAM was cleared and the machine returned to normal operation, albeit having forgotten all the cool stuff I had typed into it with the German keyboard map.

I don’t have a replacement battery for it yet, but it hardly makes sense to do extensive work until I can make a new system ROM with an English keymap and maybe also some goodies.

What’s Next?

The PC-8300 should get a new English 8300 ROM instead of the modded German 8201A ROM it seems to have now. I’d also like to put a cover over the ROMs, so I’m not constantly worried about brushing up against them and giving the machine a fatal ESD zap during operation.

The keyboard on the 102 is a little dirty, especially the “Num Lock” key, which seems to get constantly stuck when it’s only slightly brushed and needs a lot of force to free up again. Removing the keyboard was easy once I was inside the case, so maybe cleaning it will also be simple.

I would like to replace the memory batteries in both machines, but it would be nice to do it in a way that doesn’t risk leakage. Some kind of 1/2AA socket like the later Macintoshes, or even a sealed remote battery holder like some Japanese machines I’ve seen lately, would be a good option if I can understand the recharge circuit.

Barring that, I have found a local place that still sells solderable NiMH barrel batteries, so at least I can give it a like-for-like new battery that will last a few more decades. This is what other people in the Model 100 scene do with theirs, so at least it’s standardized.

Repair Summary

| Fault | Remedy | Caveats |

|---|---|---|

| Tandy 102 battery corrosion. | Remove battery, clean. | |

| PC-8300 battery corrosion. | Remove battery, clean. |